Description

TCK500 product detail page

| Parameters | TCK500 |

|---|---|

| Maximum workpiece rotation diameter on the bed mm | Φ500 |

| The maximum workpiece rotation diameter on the slide mm | Φ260 |

| Maximum workpiece processing length mm | 650 |

| Maximum processing diameter mm | Φ360 |

| X-direction/Z-direction track width mm | 35/35 |

| Servo main motor Kw | 11 |

| Spindle hole taper/spindle hole diameter mm | Φ66 |

| Pull tube through hole diameter mm | Φ48 |

| Spindle head | A2-6 |

| Spindle speed range r.p.m | 100~4500 |

| Horizontal (X) maximum stroke mm | 220 |

| Longitudinal (Z) maximum stroke mm | 750 |

| Ball screw diameter*pitch Horizontal (X) mm | φ32X10mm |

| Longitudinal (Z) mm | Φ32X10 |

| Transverse rapid feed m/min | 20 |

| Longitudinal rapid feed m/min | 20 |

| Cutting feed range | 0.01~1000 |

| Repeat positioning accuracy Horizontal (X) | 0.005mm |

| Vertical (Z) | 0.005mm |

| Workpiece machining accuracy | IT6~IT7 |

| Workpiece Surface Roughness | 有色金属≤Ra1.6μm |

| Sleeve diameter/stroke mm | Φ65 |

| Taper of sleeve hole | MT4# |

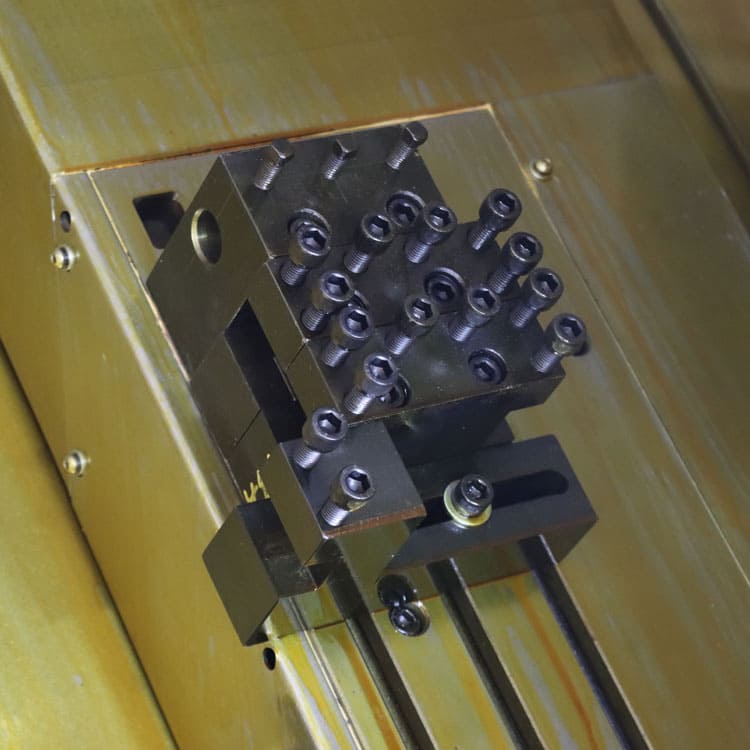

| Servo Turret | SH80-8 |

| Shank section mm | 25×25/40 |

| Overall dimension of machine tool (length*width*height) mm | 2300×1600×1800 |

| Machine Weight Kg | 4200 |

This series of tilt bed CNC lathe is a new automated metalworking equipment suitable for batch processing of axial and flat parts. It has high efficiency, easy operation, high precision and other main characteristics. This series of lathe is mainly used for external and internal cylindrical surface turning, conical surface and other rotating surfaces, as well as thread processing.

Features:

1. 45 degree tilt bed lathe

2. More accurate linear guides from Taiwan

3. Convenient large number of waste ejection – customers can choose front or rear ejection

4. X and Z axes are driven by servo motors through a rigid linkage with low inertial moment under large torque; Spindle nut adopts pre-stretching

5. Retractable cutter

6. High-speed, high-precision and rigid spindle body with servo spindle, which can achieve higher spindle speed.

7. Using advanced centralized lubrication system

8. The whole machine has full protection, reliable against water and debris, and provides convenient repair.

Standard equipment:

GSK980TC3 CNC controller

7.5kW main servo motor

Taiwan linear guides

A2-6 type spindle head with 3000rpm rotation speed.

10″ hydraulic chuck plate made in China with longitudinal hole

Hydraulic turret tool for 6 workstations

Automatic lubrication system

Automatic cooling system

Work lamp

Tools and tool box

Additional equipment:

Hydraulic three-jaw chuck plate

Turret tool for 8/12 workstations / servo motor turret tool

Ejector

Siemens 808D/FANUC CNC controller

Reviews

There are no reviews yet.