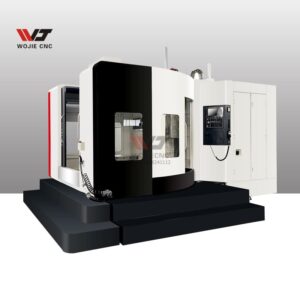

1. Vertical Machining Center (VMC)

- Features: Small footprint, ideal for processing small-to-medium-sized parts.

- Advantages: Easy workpiece clamping, suitable for milling, drilling, and other operations.

- Limitations: Machining depth is restricted; heavy parts are prone to deformation.

- Applications: Molds, electronic products, precision components.

2. Gantry Machining Center (GMC)

- Features: High rigidity, designed for heavy-duty cutting and large workpieces (e.g., aerospace components).

- Advantages: Multi-spindle configuration enables simultaneous machining.

- Limitations: High equipment cost; requires large installation space.

- Applications: Aircraft frames, ship components, wind turbine blades.

3. Horizontal Machining Center (HMC)

- Features: Efficient chip removal, suitable for long-duration machining tasks.

- Advantages: One-time clamping supports multi-face machining (e.g., box-type parts).

- Limitations: Complex programming; relatively large floor space.

- Applications: Automobile engine blocks, gearboxes, hydraulic valve bodies.

4. 5-Axis Machining Center

- Types:

- Cradle type: Workpiece rotation (A/C axis).

- Head-swing type: Spindle head swing (B/C axis).

- Selection Guidelines:

- For batch processing of small-to-medium parts → Vertical Machining Center.

- For large structural components → Gantry Machining Center.

- For multi-face machining requirements → Horizontal Machining Center.

- For complex curved surfaces or high-precision tasks → 5-Axis Machining Center (dynamic accuracy requires verification).